3D printers have made bulletproof cubes – vests and tank armor next?

‘Ultrahard polymers’ could be used across many diverse industries

The latest innovation in 3D printing – a field where fresh developments are really coming thick and fast – is the ability to create cubes which are capable of stopping bullets.

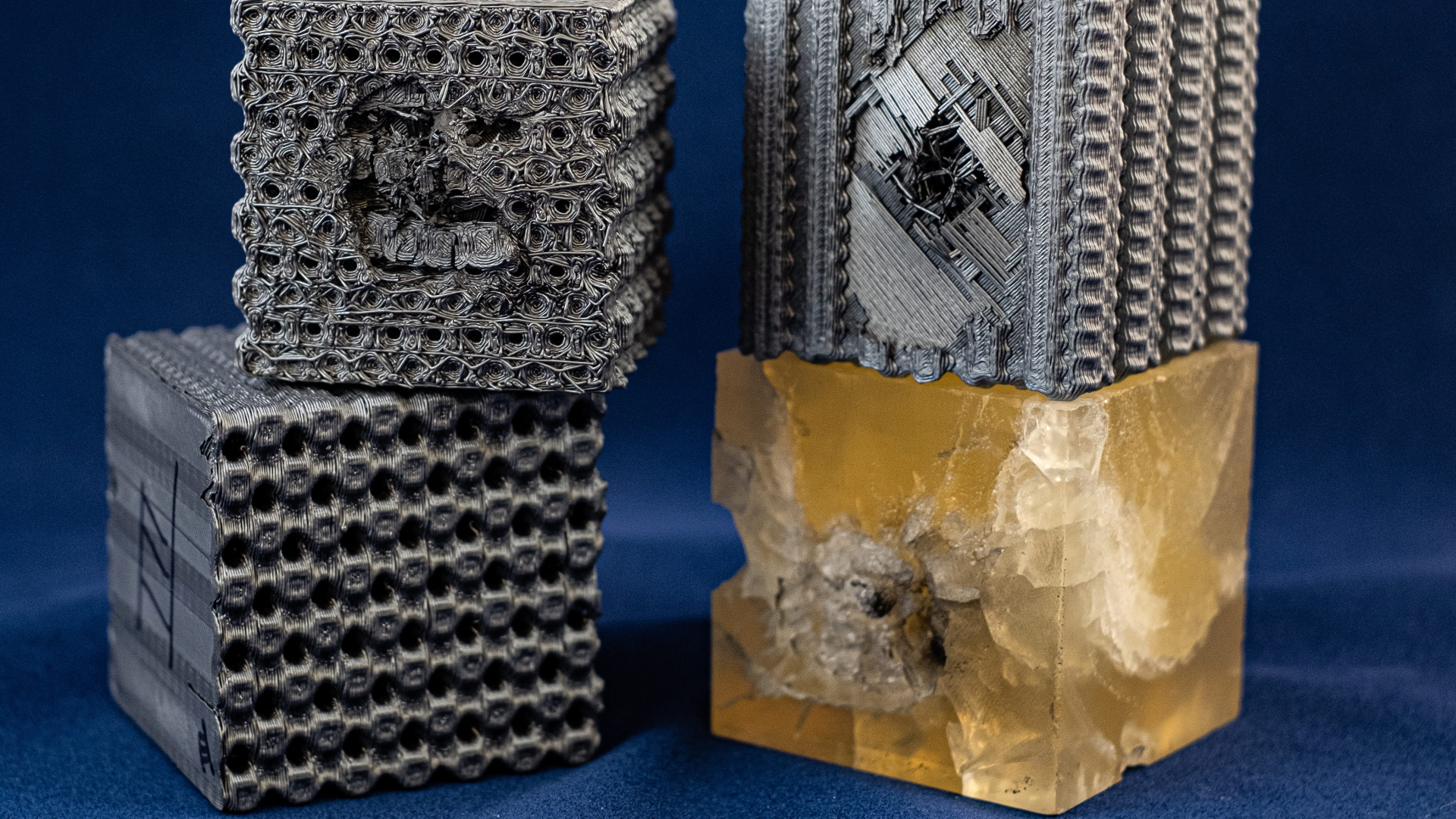

This feat was achieved by researchers at Rice University’s Brown School of Engineering, who have printed cubes of ‘tubulane-like ultrahard polymers’ which are lightweight and full of holes, but as hard as diamond.

- Here is the world’s fastest 3D printer

- How to build your own 3D printer

- These are the best 3D printers of 2019

To the point where these blocks can stop a proverbial speeding bullet, and far more effectively than a solid block of the same material. In other words, the lattice of holes has a strengthening effect – indeed, the best samples proved 10 times more effective at stopping a bullet than a solid block.

The bullet fired at 5,800m/s (a seriously fast projectile) was stopped in the second layer of the tubulane cubes, with no ‘significant structural damage’ observed beyond that layer. However, in a solid reference cube made of the same material, cracks ran all the way through the block (the bottom-right cube in the above image).

Tubulanes are structures of crosslinked carbon nanotubes, but remain as yet undiscovered and purely theoretical. But in this work, the theoretical idea has been scaled up to produce said polymer cubes – with these apparently highly impressive results.

Crushing force

Graduate student at Rice, and lead author of the project, Seyed Mohammad Sajadi, also noted that when subjected to crushing forces in a laboratory press, the tubulane blocks collapsed in on themselves without cracking.

He added that such tubulane-like structures fashioned from polymer, or indeed metal, or ceramic, would only be limited by the size of the printer making them.

Are you a pro? Subscribe to our newsletter

Sign up to the TechRadar Pro newsletter to get all the top news, opinion, features and guidance your business needs to succeed!

And furthermore that optimizing the design of the lattice could mean better materials for all sorts of industries, from automotive through to aerospace, civil engineering, and sports, or even biomedical applications.

Oil and gas companies will also likely want to adopt this kind of tech to fashion strong and durable materials that can be used in deep well construction. And given the bullet-stopping experiments going on here, it’s not hard to imagine that perhaps some kind of lightweight bulletproof vest could be concocted, or armor for military vehicles like tanks.

Meanwhile, on the building front in general, 3D printing is already being used as we recently saw with the largest (two-storey) 3D-printed building ever constructed over in the United Arab Emirates. And there’s also the prospect of autonomous eco-cities comprising of 3D-printed houses made principally from mud (yes – just the soil right there on-site).

Via Gizmodo

Darren is a freelancer writing news and features for TechRadar (and occasionally T3) across a broad range of computing topics including CPUs, GPUs, various other hardware, VPNs, antivirus and more. He has written about tech for the best part of three decades, and writes books in his spare time (his debut novel - 'I Know What You Did Last Supper' - was published by Hachette UK in 2013).